|

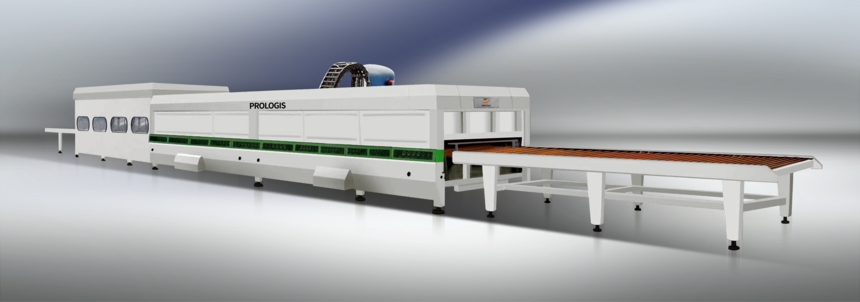

LPG-2F(R)Glass Double-Chamber Tempering Furnace The Glass Double-Chamber Tempering Furnace is a high-efficiency system designed for tempering flat glass. It features two separate heating chambers, allowing for enhanced production capacity and improved energy efficiency.

Description

The Glass Double-Chamber Tempering Furnace is a highly efficient system designed to optimize glass tempering through its innovative dual-chamber design. It is engineered to enhance production capacity, reduce energy consumption, and deliver high-quality tempered glass for various applications, including architectural and automotive industries.

Key Features: Dual Temperature Zones: The furnace features two distinct heating chambers, each with independent temperature zones. This dual-zone design ensures precise temperature control across the glass surface, reducing energy consumption while increasing both production output and product quality. Advanced Heating Methods: The front chamber is equipped with options for hot air circulation or compressed air heating. These advanced heating methods ensure better heat distribution, improving glass quality and enhancing overall production efficiency. Independent Roller Drive Systems: Each chamber operates with separate roller drive motors, allowing for precise control over the glass handling process. The synchronized automatic control of roller speed between chambers ensures consistent glass movement and minimizes speed shocks, leading to smooth operation and higher production accuracy. Improved Product Quality: The furnace’s design and heating systems work together to achieve uniform heating, which results in high-quality tempered glass with fewer defects. The system is capable of tempering glass at faster speeds while maintaining precision. This Glass Double-Chamber Tempering Furnace is ideal for glass manufacturers looking to increase production efficiency while reducing energy consumption and maintaining high product quality. The flexibility in heating methods and precise control of glass handling make it a cutting-edge solution for high-volume tempering operations. Technical Specification

|