|

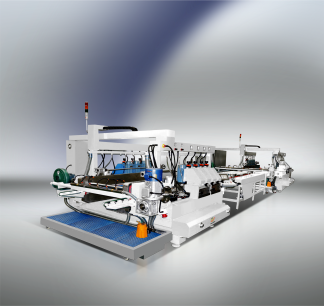

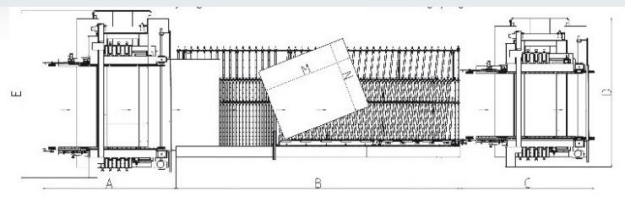

LZYSM 1510EGlass Automatic Production Line LZYXM 1510E Glass Straight-Line Double Pencil Edging Production Line consists of two straight-line double edge machines and one straight-line transfer table. The configuration and width can be customized according to customer requirements, such as models 2520, 2515, 1515, and 1510. The system utilizes PLC control, with parameters for processing width and speed set via an interface. High-precision double linear guide rails and dual ball screw drives ensure accuracy in processing dimensions. It is suitable for processing thin glass with thicknesses ranging from 2.8mm to 8mm. The machine offers high edging speed and transfer efficiency, making it ideal for deep processing of industrial glass. It is compatible with washing machines, tempering lines, and other equipment, and is an efficient edging solution for solar glass.

Description

LZYXM 1510E Glass Straight-Line Double Pencil Edging Production Line is a specialized system designed for precision grinding and polishing of the round edges on flat glass sheets. This production line is widely used in industries requiring high-quality edge finishing for various glass products, including architectural, automotive, and decorative glass. The core of the production line consists of one or more straight-line double pencil edging machines. These machines are engineered to simultaneously grind and polish both pencil edges of the glass sheets, enhancing efficiency and consistency.Equipped with dual grinding heads, the machines perform accurate edge profiling and polishing, ensuring uniform round edges on both sides of the glass. The machines allow for precise adjustment of grinding parameters, including edge radius, to meet specific design requirements. The production line includes a straight-line transfer table that ensures smooth and accurate movement of the glass sheets through the grinding process. The transfer table automatically positions and moves the glass sheets, reducing manual handling and minimizing the risk of damage or misalignment. It is designed for high-speed operation, improving overall production efficiency by quickly and precisely transferring glass sheets between different stages of processing. The production line is controlled by PLC system, which manages the operation of the grinding machines and transfer table. The PLC system features an intuitive interface for setting and adjusting processing parameters such as edge radius, grinding speed, and width. The system ensures accurate control over grinding and polishing operations, resulting in consistently high-quality edge finishes. The production line is equipped with high-precision linear guide rails and ball screw drives, which contribute to the accuracy and stability of the grinding process. These components are designed for durability and precision, ensuring long-term performance and reliability. The combination of guide rails and ball screws reduces vibration and improves the quality of the finished edges. The glass straight-line double round edge grinding production line can be integrated with other glass processing equipment, such as washing machines, tempering lines, and laminating systems. This allows for a seamless workflow from initial processing to final product, making it suitable for various glass manufacturing applications. Integration with other systems improves overall production efficiency and quality control. The production line streamlines the grinding and polishing processes, allowing for faster production and reduced labor costs.Precision control and high-quality components ensure uniform edge finishes, meeting strict industry standards. The production line accommodates various glass sizes and thicknesses, making it adaptable to different manufacturing needs. Automated handling and integration with other processing equipment improve overall workflow and production efficiency. Technical Specification

|

||||||||||||||||||||||||||||||||||||||||