|

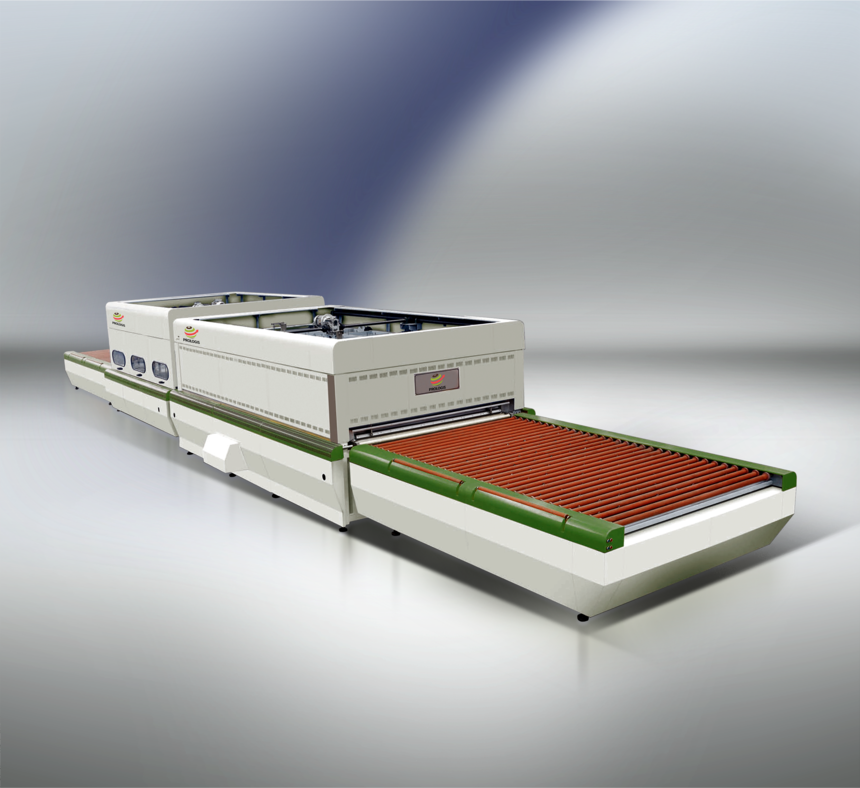

LDPG-A/FFlat Glass Convectional Tempering Furnace Flat Glass Convectional Tempering Furnace is an efficient equipment used for tempering flat glass. It utilizes fan convection heating technology, where forced hot air is circulated evenly to heat the glass, ensuring consistent heating results, reducing surface temperature variations, and improving the overall tempering quality.

Description

Flat Glass Convectional Tempering Furnace The Flat Glass Convectional Tempering Furnace is an advanced tempering system designed to provide efficient, uniform heating and superior quality results for flat glass. This system leverages compressed air convection technology to ensure optimal heat distribution, which is essential for achieving high precision and consistent glass tempering. Key Features of the LDPG Series: LDPG-A Series: Mature and Stable Heating System: The LDPG-A series incorporates a proven matrix-arranged electric heating system combined with a high-temperature, high-pressure jet airflow heating system. This arrangement ensures uniform heat distribution across the entire glass surface. High-Temperature Spiral Convection Heating Pipes: These are resistant to extreme temperatures and provide stable, consistent heating. Fan-Shaped Nozzle Design: The fan-shaped nozzles used for airflow further enhance even heat application, reducing the risk of localized overheating or cold spots. Reliable and Efficient Performance: As a patented and mature product, the LDPG-A series is known for its operational stability, high production efficiency, ease of maintenance, and low failure rate, making it ideal for high-volume industrial glass tempering applications.

LDPG-F Series: Forced Internal Circulation with High-Temperature Fans: The LDPG-F series utilizes high-temperature fans that circulate hot air within the furnace, ensuring even heat distribution. These fans are controlled using variable frequency drives to adjust their speed as needed, allowing for precise temperature management. Optimized Wind Path and Hole Layout: The design of the wind path and hole arrangement ensures efficient airflow, enabling the uniform heating of the glass. Air Duct Temperature Measurement System: This system allows the LDPG-F series to automatically regulate hot air speed based on temperature conditions, ensuring the best possible heating mode for the glass being tempered. Energy Efficiency and Productivity: The LDPG-F series, with its patented design, ensures low energy consumption and high production efficiency, making it both cost-effective and highly reliable for industrial use. Benefits: Uniform Heating: Both series of the LDPG tempering units ensure consistent heat application, which is crucial for achieving high-quality tempered glass. Efficiency: The combination of electric heating and air convection allows for faster heating times and increased production efficiency. Operational Stability: With patented technology and high-quality components, the system operates with minimal downtime and reduced maintenance needs. Adaptability: These systems are designed to handle a wide range of glass thicknesses and types, from low-E glass to standard float glass.

Applications: Architectural glass for building facades and interiors Automotive glass for windows and sunroofs Furniture glass and decorative glass products The Flat Glass Convectional Tempering Furnace is an ideal choice for manufacturers seeking high-performance glass tempering equipment that delivers reliable, energy-efficient, and high-quality results across various glass applications. Technical Specification

|