|

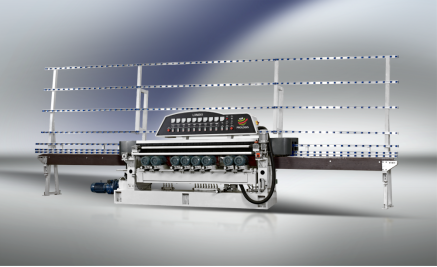

9 Motors LXM 261Glass Beveling Machine LXM 261 Glass Beveling Machine is suitable for grinding the straight-line bevel and bottom edges of flat glass sheets. It performs coarse grinding, fine grinding, polishing of the bevel edges, and grinding of the bottom edge in a single pass. The machine features a direct-drive grinding head motor, which is compact, operates quietly, and is low-maintenance. It controls the dual-screw angle adjustment with a digital display for glass thickness and angle settings. The machine boasts advanced structure, high precision, ease of operation, and a wide processing range.

Description

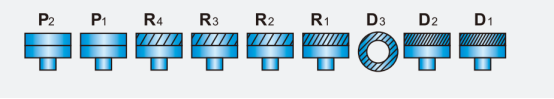

LXM 261 Glass Beveling Machine is a specialized tool designed for precision beveling and edge finishing of flat glass sheets. This machine is equipped with a sophisticated grinding wheel assembly, making it ideal for achieving high-quality beveled and polished edges on glass products. The machine features a versatile grinding wheel assembly consisting of: 2 Coarse Diamond Wheels: These are used for the initial coarse grinding of the glass edges, efficiently removing material and shaping the bevel. 6 Fine Grinding and Polishing Wheels: These wheels follow the coarse grinding stage, providing fine grinding and polishing to achieve a smooth, high-quality finish. 1 Semi-Pencil Bottom Edge Wheel: This wheel is designed specifically for grinding and finishing the bottom edges of the glass, ensuring a rounded, polished edge. The combination of coarse and fine grinding wheels allows the machine to handle a range of beveling tasks, from initial shaping to final polishing. This versatility ensures that the machine can produce various bevel angles and edge profiles to meet specific design requirements. It is built with robust materials and precision components to ensure durability and reliable performance. The grinding wheels are designed for long-lasting use and consistent results, even under continuous operation. The machine is designed for user-friendly operation, with straightforward controls for adjusting grinding parameters and settings. This ease of use helps operators achieve accurate and consistent results with minimal training. The machine’s comprehensive wheel assembly allows for efficient processing of glass edges, combining coarse grinding, fine grinding, and polishing in one setup. The precise control and high-quality components ensure uniform edge finishing, meeting rigorous industry standards. The machine’s ability to handle various bevel angles and edge profiles makes it adaptable for different glass processing needs. Built with robust materials and components, the machine is designed for long-term reliability and performance. Technical Specification

Distribution of Wheels

|