|

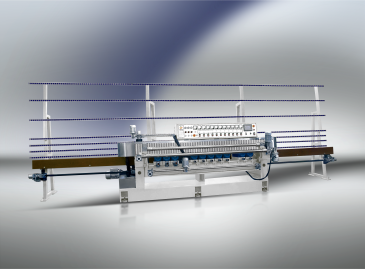

11 Motors LXM 371PGlass Beveling Machine The LXM 371P Glass Beveling Machine is a multifunctional model developed by our factory in response to market needs, incorporating features from various domestic and international beveling machine series. It is designed with a chainless bearing rolling chain plate structure, ensuring smooth glass transmission, high processing speed, and stable quality. The machine includes an adjustable rear beam, offering a wide processing range.

Description

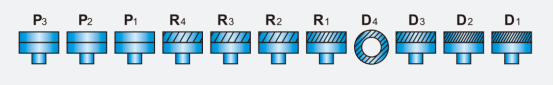

The Glass Beveling Machine LXM 371P is a state-of-the-art model developed to meet diverse glass processing needs. Building upon the sophisticated features of the LXM 371SJ, this model integrates several advanced functionalities, making it ideal for high-precision beveling and bottom edge processing of flat glass or mirrors. Key Configuration: 3 Coarse Diamond Grinding Wheels: These wheels are used for the initial rough grinding of glass bevels, ensuring efficient material removal and accurate shaping. 7 Fine Grinding and Polishing Wheels: Following the coarse grinding, these wheels handle the fine grinding and polishing stages, delivering a smooth, high-quality finish. 1 Semi-Round Bottom Edge Wheel: This specialized wheel processes the bottom edge of the glass, providing a clean and precise finish. The LXM 371P employs a chainless bearing rolling chain plate system, ensuring smooth and stable glass transport. This design enhances processing speed and consistency while reducing maintenance and improving durability. The machine includes an adjustable rear beam that allows for easy modification of the processing range, accommodating various glass sizes and thicknesses. Versatile Processing Capabilities: Minimum Glass Size: Capable of processing small glass pieces as tiny as 25mm x 25mm. Maximum Bevel Width: Supports a wide range of bevel widths, providing flexibility for different production requirements. It can process glass with beveling angles ranging from 0° to 30°, offering additional versatility for a variety of glass beveling needs. The chainless bearing rolling chain plate structure ensures smooth and stable glass transport, resulting in faster processing speeds and consistent quality. The adjustable rear beam and versatile wheel configuration make the LXM 371P suitable for processing various glass sizes and thicknesses, from small pieces to larger sheets. The machine features a user-friendly control system with a digital display, providing real-time information on glass thickness, processing speed, beveling angle, and other key parameters. This allows for precise control and easy operation. The LXM 371P is designed specifically for beveling and processing the bottom edges of various flat glass or mirror pieces, making it a valuable tool for users who require high precision and efficiency in their glass processing operations. The Glass Beveling Machine LXM 371P combines advanced design with enhanced functionality, offering superior precision, efficiency, and versatility for a wide range of glass processing applications. Technical Specifications

Distribution of Wheels:

|