|

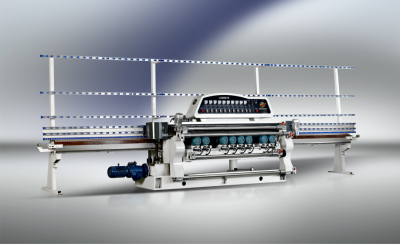

9 Motors LXM 261BGlass Beveling Machine LXM 261B Glass Beveling Machine is designed for grinding the straight-line bevels and bottom edges of flat glass sheets. It performs coarse grinding, fine grinding, and polishing of the bevels, as well as grinding of the bottom edge, all in a single operation. It features a direct-drive grinding head motor, which is compact, operates quietly, and requires minimal maintenance. The motor controls the dual-screw angle adjustment, with digital displays for glass thickness, speed, and angle. Additionally, it includes a front beam lifting function. The machine boasts an advanced structure, high precision, ease of operation, and a wide processing range, making it a specialized tool for simultaneously processing both direct and small bevels.

Description

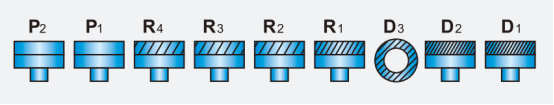

LXM 261B Glass Beveling Machine is an advanced version of the model LXM 261, specifically designed to provide even greater flexibility, precision, and efficiency in the processing of flat glass sheets. And an expanded range of beveling angles from 3° to 45°.With structural improvements and additional features, LXM 261B is ideal for producing high-quality bevels and polished edges, catering to a wide range of glass processing needs. LXM 261B model introduces a more advanced and robust structural design, ensuring improved stability and durability during operation. This reinforced design allows the machine to maintain high precision over extended periods of use, making it suitable for demanding production environments. One of the major enhancements in the LXM 261B is the addition of a front beam lifting function. This feature enables greater flexibility in the adjustment of the machine, making it easier to accommodate different glass thicknesses and sizes. The ability to raise and lower the front beam allows for more accurate control of the beveling process, particularly when dealing with varying glass dimensions. Unlike many standard beveling machines, LXM 261B can effectively process small glass pieces as small as 20x20mm. This capability is essential for industries requiring precision edge finishing on smaller, more intricate glass components, such as those used in decorative applications, fine furniture, or specialty glazing projects. One of the major improvements in the LXM 261B is its expanded range of beveling angles, from 3° to 45°. This wide range allows manufacturers to achieve both subtle and steep bevels, catering to a diverse set of applications, from architectural glass and decorative installations to more complex designs. Grinding Wheel Assembly: As with the original model LXM 261, LXM 261B is equipped with a versatile grinding wheel assembly, consisting of: 2 Coarse Diamond Wheels for initial shaping of the bevel edges. 6 Fine Grinding and Polishing Wheels to refine and polish the bevel, delivering a smooth, high-quality finish. 1 Semi-Round Bottom Edge Wheel for the precise grinding and polishing of the bottom edges. The machine continues to feature a direct-drive grinding head motor, known for its compact design, low noise levels, and minimal maintenance requirements. This motor ensures the machine operates smoothly and efficiently while reducing the risk of mechanical failures. Digital Control System: The LXM 261B comes with an advanced digital control system, offering precise adjustments of processing parameters, including glass thickness, beveling angle, and speed. The system allows for easy parameter setup through an intuitive interface, displaying real-time values for glass thickness, speed, and angles, further enhancing operational efficiency. Dual-Screw Angle Adjustment: The dual-screw angle adjustment mechanism ensures highly accurate control of the bevel angle, enabling consistent results across multiple production runs. This system is particularly beneficial when working with varying glass sizes or complex beveling requirements. With its advanced structure and front beam lifting capability, the LXM 261B can handle a broader range of glass sizes and thicknesses, including small pieces that would be challenging for conventional machines. The combination of the dual-screw angle adjustment and digital control system ensures that the machine delivers consistent, high-quality edge finishes with minimal operator intervention. The machine’s ability to process glass pieces as small as 20x20mm makes it ideal for industries requiring fine, intricate edge work. The integration of advanced features, such as the front beam lifting function and the direct-drive motor, reduces processing time and ensures smooth, uninterrupted operation, even in high-volume production settings. The Glass Beveling Machine LXM 261B builds on the strengths of the original model, offering enhanced performance, precision, and versatility for modern glass processing. With its ability to handle small glass pieces and its advanced structural features, the LXM 261B is the ideal choice for manufacturers looking for a high-efficiency beveling solution with broad application potential. Technical Specification

Distribution of Wheels

|