|

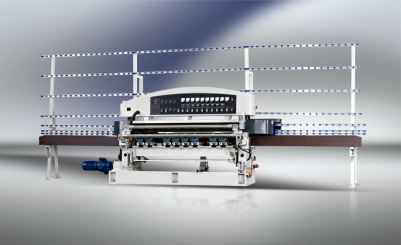

9 Motors LXM 261SJGlass Beveling Machine LXM 261SJ Glass Beveling Machine is suitable for grinding the straight-line bevels and bottom edges of flat glass sheets. It completes coarse grinding, fine grinding, polishing of the bevels, and grinding of the bottom edge in one operation. The direct-drive grinding head motor features a compact design, low noise, and minimal failure rates. The motor controls the dual-screw angle adjustment, with a digital display showing glass thickness, speed, and angle. It also includes a front beam lifting function. With its advanced structure, high precision, ease of operation, and wide processing range, this specialized machine is designed for processing both standard and small bevels simultaneously.

Description

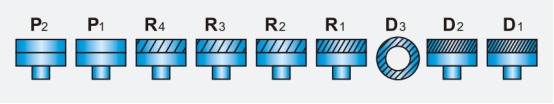

The Glass Beveling Machine LXM 261SJ is an advanced upgrade of the original LXM 261, offering enhanced structural design, additional functionality, and the capability to process small glass pieces with high precision. With its ability to handle glass as small as 20x20mm, the 261SJ model is ideal for industries that require precise beveling and edge finishing for both large and small glass sheets. Additionally, it offers adjustable beveling angles from 3° to 30°, making it a versatile solution for high-precision edge finishing in various applications. The LXM 261SJ features a more sophisticated and durable structure, providing improved stability and reliability during operation. This advanced design ensures high precision and consistent performance, even in high-demand production environments, making it suitable for both small-scale and industrial-scale processing. One of the notable upgrades in the 261SJ model is the inclusion of a front beam lifting function. This feature allows for flexible adjustments to accommodate different glass thicknesses, enabling more accurate control of the beveling process. The ability to raise and lower the front beam is particularly useful when working with a wide range of glass dimensions. A key advantage of the 261SJ is its capability to process glass pieces as small as 20x20mm. This makes it ideal for manufacturers requiring the fine processing of small, intricate glass components, such as those used in decorative panels, fine furniture, or specialty glazing. This feature sets the 261SJ apart from conventional beveling machines that may struggle with small glass sizes. One of the standout features of the LXM 261SJ is its ability to process glass bevels at angles ranging from 3° to 30°. This wide range of angle adjustment makes the machine highly versatile, allowing it to handle various beveling requirements, from subtle to more pronounced edges. This flexibility is especially useful in architectural glass, decorative applications, and custom glass designs. The LXM 261SJ retains the sophisticated grinding wheel system from the 261 model, which includes: 2 Coarse Diamond Wheels: These perform the initial rough grinding, shaping the glass bevel efficiently. 6 Fine Grinding and Polishing Wheels: These wheels ensure smooth, high-quality bevel finishing through fine grinding and polishing. 1 Semi-Round Bottom Edge Wheel: Specially designed to grind and polish the bottom edge of the glass. The machine’s direct-drive grinding head motor offers a compact design, low noise, and minimal maintenance. This ensures the machine operates quietly and efficiently, with reduced mechanical downtime, making it a reliable choice for continuous production. The dual-screw angle adjustment system enables precise control over the beveling angle, ensuring consistent results across multiple glass sheets. The digital display provides real-time data on the glass thickness, processing speed, and angle, making it easier for operators to set up and monitor the process for optimal accuracy. The ability to process glass pieces as small as 20x20mm ensures that the LXM 261SJ can handle intricate glasswork with exceptional precision, making it ideal for decorative and detailed projects. The advanced structural design, along with the front beam lifting function, ensures the machine can handle both small and large glass pieces with ease, maintaining consistent precision even in long production runs. The front beam lifting mechanism offers increased flexibility, allowing the machine to easily adjust to different glass thicknesses and sizes. This makes the 261SJ a versatile solution for manufacturers processing a variety of glass products. With a digital display that provides real-time information on key processing parameters, operators can easily set up and monitor the beveling process, ensuring efficient operation and minimizing setup time. The Glass Beveling Machine LXM 261SJ builds on the strengths of the original 261 model, offering advanced features such as small glass processing, front beam adjustability, and a more durable structure. This makes the 261SJ an excellent choice for manufacturers looking to enhance their beveling capabilities while achieving high-precision results, particularly when working with small and intricate glass pieces. Technical Specification

Distribution of Wheels

|