|

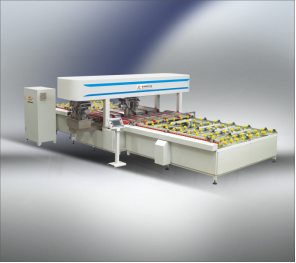

Four-side Edging LFZM 3625Glass Straight-Line Four-Side Edging Machine LFZM 3625 High Speed Glass Straight-Line Four-Side Edging Machine is designed to simultaneously grind and polish all four edges of flat glass sheets. This machine ensures uniform edge finishing by processing the glass through multiple grinding and polishing stages, achieving smooth and precise edges on all sides. It is widely used in various industries for producing high-quality glass for applications such as windows, mirrors, and decorative panels, offering efficiency and consistent edge quality in a single operation.

Description

LFZM 3625 High Speed Glass Straight-Line Four-Side Edging Machine is a specialized piece of equipment designed for the precise grinding and polishing of all four edges of flat glass sheets. This machine is essential in the glass processing industry for producing high-quality, finished glass suitable for various applications. The machine is capable of grinding and polishing all four edges of the glass simultaneously, which enhances efficiency and consistency in edge finishing. This feature significantly reduces processing time compared to machines that handle fewer edges at a time. Typically, the machine includes several stages of grinding and polishing. These stages use different types of abrasives and polishing tools to achieve a smooth, high-quality finish. Operators can adjust the machine’s settings to accommodate different glass sizes, thicknesses, and edge profiles. This flexibility makes the machine suitable for a wide range of glass products, from thin decorative panels to thicker architectural glass. Modern glass four-edge grinding machines are equipped with advanced control systems, including CNC . This allows for precise adjustment of grinding angles, edge dimensions, and processing speeds, ensuring consistent quality and accuracy. Many machines feature automated loading, positioning, and unloading systems. This automation reduces manual labor, minimizes handling errors, and increases overall production efficiency. Glass sheets are moved through the machine on conveyor belts or rollers, ensuring smooth and accurate processing. The machine is typically built with robust materials and components, including high-quality grinding wheels, guide rails, and motors. This ensures durability and long-term reliability, even under continuous operation in demanding industrial environments. By processing all four edges simultaneously, the machine significantly reduces production time and increases throughput. The precise control and multiple processing stages ensure uniform edge quality, meeting high industry standards. Adjustable settings and automated handling make the machine adaptable to various glass sizes and types, making it suitable for diverse applications. Automation reduces the need for manual handling, cutting down on labor costs and minimizing the risk of errors. Technical Specification

|