|

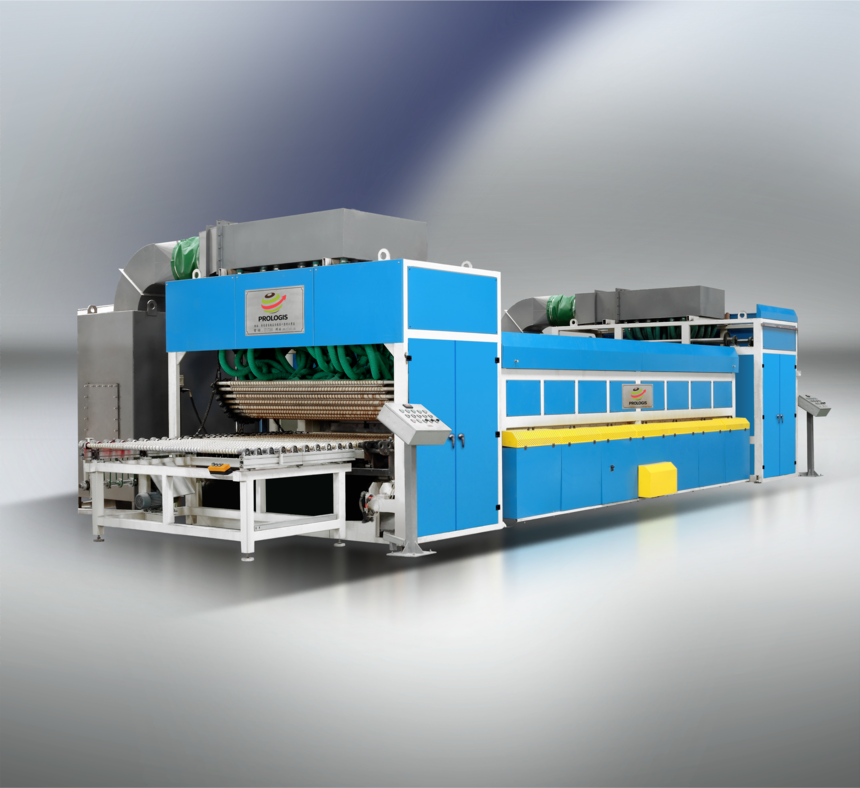

LWG(H) SeriesGlassl Bending Tempering Furnace The Glassl Bending Tempering Furnace LWG(H)Series is a specialized glass processing machine designed for the production of bent tempered glass. This type of glass is widely used in automotive, architectural, and decorative applications where curved glass with high strength is required.

Description

The Glassl Bending Tempering Furnace is a specialized machine designed for the bending and tempering of flat glass, enabling the production of curved glass products that meet the demands of various industries, including automotive, architecture, and interior design. Key Features and Components: Horizontal Loading System: The glass is placed horizontally on a conveyor system, which minimizes stress and deformation during the bending process. This orientation allows for better control of the bending angle and shape. Bending Mechanism: The furnace employs a series of hard-axis upper and lower rollers that press the glass into the desired curvature. The rollers are designed to create accurate and smooth single-curved surfaces without spherical distortion. Adjustable Roller Spacing: The bending section features adjustable roller spacing, with a minimum distance of 80mm between rollers. This flexibility allows for different bending radii and ensures that the glass surface remains free of roller marks. Dual Roller Drive Options: The machine can operate with both upper and lower rollers rotating simultaneously or with the lower rollers driven independently. This versatility enhances control over the bending process. High Precision and Repeatability: The design ensures high repeatability and precision in the curvature of the glass. The furnace can achieve minimal edge radii and smooth transitions, making it suitable for complex shapes. Automatic and Manual Arc Adjustment: The furnace features both automatic and manual arc adjustment modes, enabling quick and precise changes to the bending parameters, which enhances productivity. Multi-Station Production Capability: The machine can accommodate multiple workstations, allowing for simultaneous processing of several glass pieces. This significantly increases production efficiency and reduces cycle times. Energy Efficiency: Designed with energy-saving features, the furnace minimizes energy consumption while maximizing output, making it an economical choice for manufacturers. Applications: Automotive Glass: Production of curved windshields, side windows, and rear windows. Architectural Glass: Creation of curved glass facades, partitions, and structural elements in buildings. Furniture and Decorative Glass: Fabrication of custom-shaped glass panels for furniture and interior decor. The Horizontal Bending Tempering Furnace is an essential tool for glass manufacturers looking to produce high-quality, curved tempered glass. With its advanced features and capabilities, it not only ensures precision and efficiency but also meets the evolving needs of the glass industry. Technical Specification

|